Shenzhen Jiding Technology Co., Ltd(JiDing) is a high tech company

with independent R&D Capability. Its engineering team has many

years and much experience on high precision molds design and

manufacturing, rapid heating and cooling central temperature

control system. Its research ranges cover rapid heating and cooling

mold designs, equipment and central control system. Its team

members are with much experience on injection production also.

The company has intelligent properties and patents on mold

temperature controlling mahcine. JiDing’s mold machine got CE

certification and was underwritten by international insurance

company(Fubon Insurance) .

JiDing had designed more than 1000 sets of mirror or texture molds

for customers. Now its one cycle heating and cooling mold

temperature machine has developed into its 7th generation also.

JDmoulding is an injection total solution provider, we ensure

services from idea to drawing to mold design to finished products

launched to market.

Our Moto: Best Energy Saving, Best Service

Rapid Heating and Rapid Cooling injection Technology Faetures and

Advantages

1.Make plastic part structure more sturdy,stress tolerance and

falling tolerance,after eliminating flow mark,vent mark and welding

line on product surface.

2.Eliminate rich fiber on product surface made by fiber glass

material,can reach Mirror effect of fiber glass material product

and strength its hardness and anti-scartching(PC+50%GF Applicable)

3.Eliminate welding line,vent mark and improve stress marks on

textured surface,and reach more clear and natural texture under

even mold temperature.

4.Rapid temperature rising and cooling inside mold may improve or

eliminate rib mark,stress mark and inner stress mark,and so on.

5.Eliminate welding lines on plastic parts to be plated,reduce

cracks on plated surface.Free of polishing process before

plating,increase yield rate of plating parts and make plated parts

with perfect appearance.

6.Rapid temperature rising and cooling,front mold and rear mold

temperatures can be adjusted independently,issues of shrinkage,

transform and warpage are settled,injection part dimension is more

precise.

7.When moulding under high mold temperature,melt resin flow well

inside mold,injection pressure reduced,energy save and lifespan of

injection machine last long.

8.Can eliminate hot runner mark and make injection part perfect.

9.For thick wall of plastic parts,rapid heating and rapid cooling

production advantage is obvious,and reduces 30-40% cycle time.

10.Rapid heating and rapid cooling injection technology coordinates

with many paint free materials,it's not limited by product

structure.Parts made by Rapid heating and rapid cooling injection

technology are perfect in appearance,and realize painting free to

avoid second time processing and cost saving.

What we do :

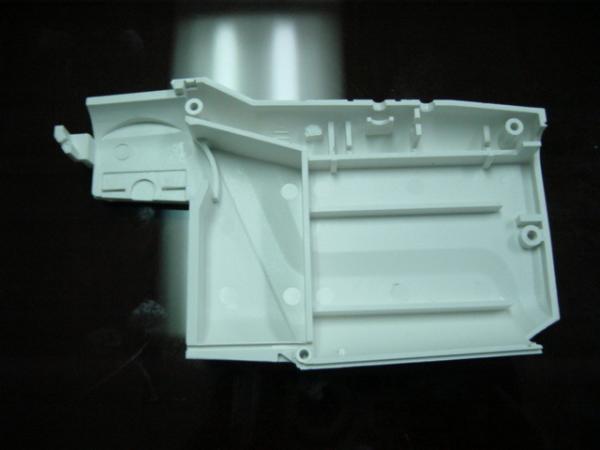

1. High precision mold design and manufacturing

2. Mold Temperature Controlling machine Design and Manufacturing

3. Plastic Injection Production

4. Product Total Solution Provider

5. Game Station accessories design and manufacturing

6. Electronic Products Design and Manufacturing

7. Mirror or Texture Molds Design and Manufacturing

8. Home Apliance Molds Design and Manufacturing

9. Medical Product Molds Design and Manufacturing

10. Automobile Interior Parts and Precision Accessory Design and

Manufacturing

11.Daily Skin Care Package Molds Design and Manufacturing

12.Painting Free Injection Parts design and manufacturing

13.Home Apliance Frames design and manufacturing

14. Rich Fiber Parts design and manufacturing

15. Plating Parts design and manufacturing

Supply Chains

Our Clients: